Isiphakeli sezintambo ezimbili esisebenza ngokuzenzakalelayo

I-multifunctional automatic wire feeder,

,

Kuphephile.– Safe

Ucwaningo oluzimele nokuthuthukiswa kwesistimu yokuthola ukuphepha, misa inani lama-alamu okuphepha, ukuphepha nokuzinza

Ukonga isikhathi – kuyasebenza futhi kuyasiza

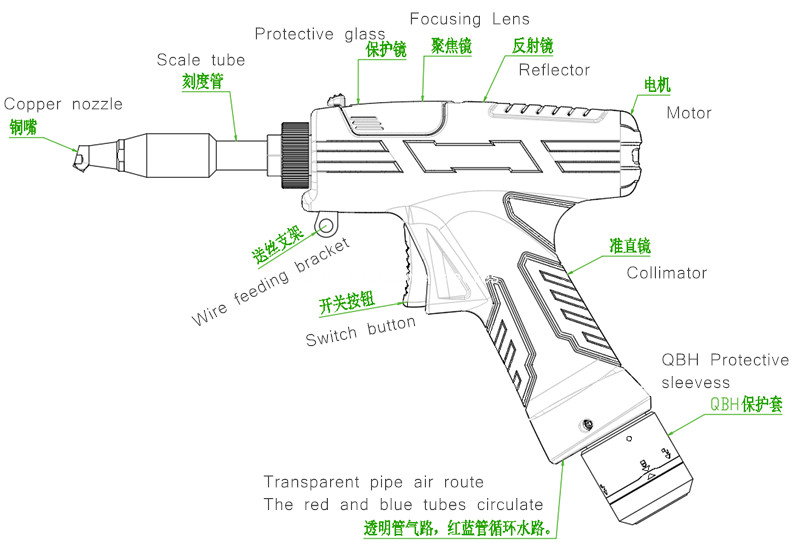

Isibuko sokugxilisa, idrowa lesibuko sokuvikela, ukushintshwa okulula

Ukukhanya - Ukukhanya kunciphisa umthwalo

Usayizi omncane, isisindo esilula, ukusebenza okuguquguqukayo, kulula ukuyisebenzisa

Ikhwalithi - i-welding enhle - ukusebenza okuzinzile

Amandla e-welding aphezulu, i-deformation encane, ukujula kokuncibilika okuphezulu

Ukusebenza - izici eziningi

Sekela ukushisela okubanjwa ngesandla okuqhubekayo, ukushisela indawo, ukuhlanza, ukusika, “isandla” “kusukela” – umzimba, ukugunyazwa kwephasiwedi

Ikhanda le-Super welding liyikhanda lokusika elibamba ngesandla elethulwa ngo-2019. Umkhiqizo uhlanganisa izibhamu zokushisela ezibanjwa ngesandla kanye nezinhlelo zokulawula ezithuthukisiwe, futhi ifakwe ama-alamu amaningi okuphepha namandla aphephile asebenzayo kanye nezilungiselelo zokuvala ukukhanya.Lo mkhiqizo ungashintshwa ukuze ube nemikhiqizo ehlukahlukene ye-fiber lasers;umklamo owenziwe kahle we-optical kanye namanzi opholile uvumela ikhanda le-laser ukuthi lisebenze ngokuzinza isikhathi eside ngaphansi kuka-3000W.

1)Qinisekisa isisekelo esithembekile ngaphambi kokunikezwa kwamandla.

2) Inhloko yokukhipha i-laser ixhunywe nekhanda lokushisela.Sicela uhlole inhloko yokukhipha i-laser ngokucophelela uma uyisebenzisa ukuvimbela uthuli noma okunye ukungcola.Lapho uhlanza ikhanda eliphumayo le-laser, sicela usebenzise iphepha lelensi elikhethekile.

3) Uma okokusebenza kungasetshenziswa ngokuhambisana nezindlela ezibalulwe kule ncwadi, kungase kube sesimweni esingavamile sokusebenza futhi kubangele umonakalo.

4) Uma ushintsha ilensi yokuzivikela, sicela uqiniseke ukuthi uyayivikela.

5) Sicela uqaphele: Uma usebenzisa okokuqala, lapho ukukhanya okubomvu kungakwazi ukuphuma emlonyeni wethusi, qiniseka ukuthi awukhiphi ukukhanya.

Imininingwane Yokulethwa Kwephakheji

Imininingwane yokulethwa kwephakheji yekhanda lokushisela elibanjwa ngesandla

★ Isendlalelo sokuqala

Ikhanda le-SUP20S lokushisela i-1pc

Isethi yesistimu 1

Ikhebula lesistimu lisezingeni elingu-10m

★ Isendlalelo sesibili

Umbhobho wethusi 7pcs Cutting nozzle 1pc

Isikali tube 1pc

Ilensi yokuzivikela 10pcs

I-Ground clamp 1 pc

Ikhebuli yokuxhuma isikrini 1m

Bonisa ibhande lesikrini 1set

Isendlalelo sesithathu

Bonisa isikrini 1pcs

ukushintsha kwamandla 2pcs

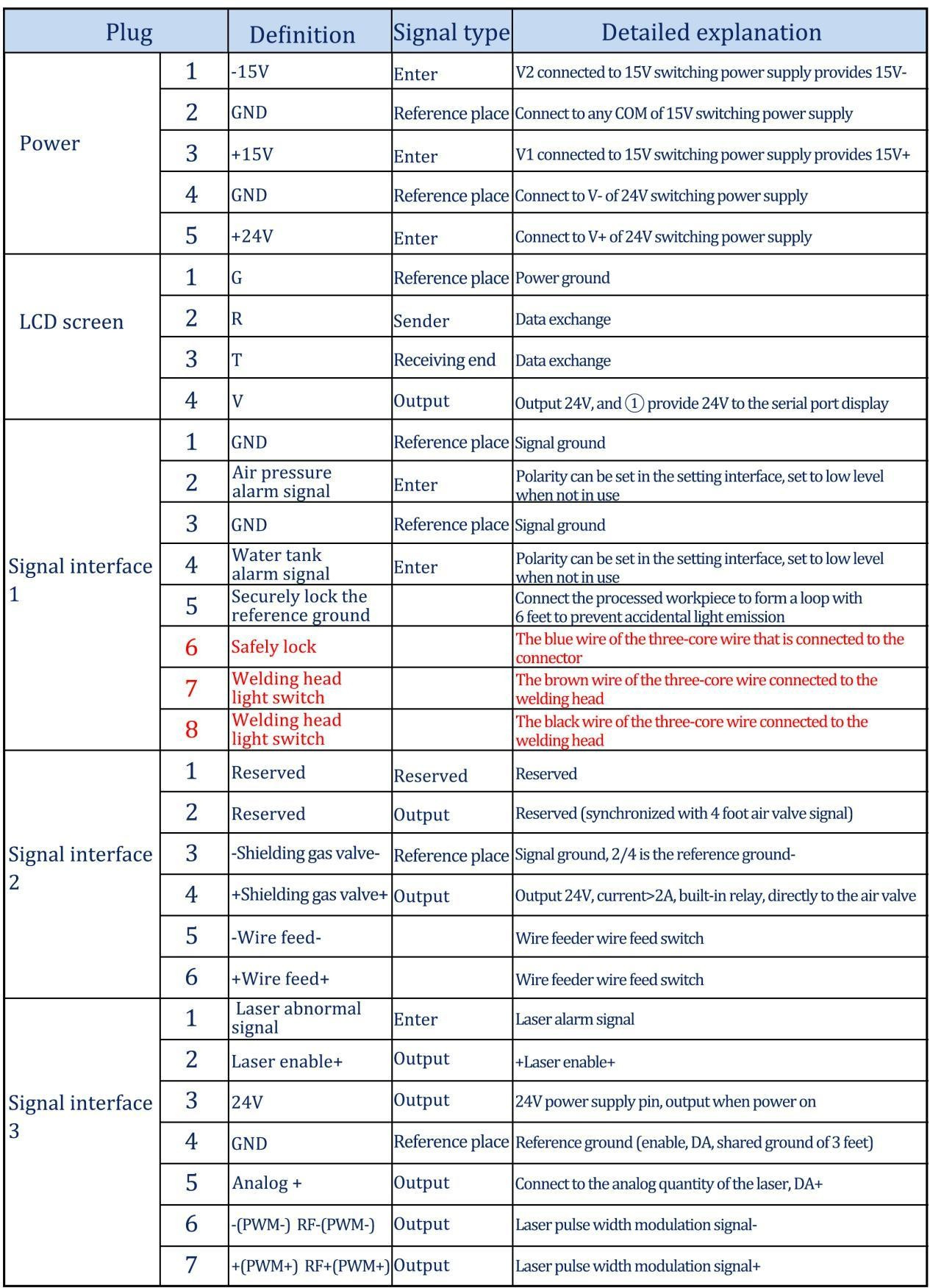

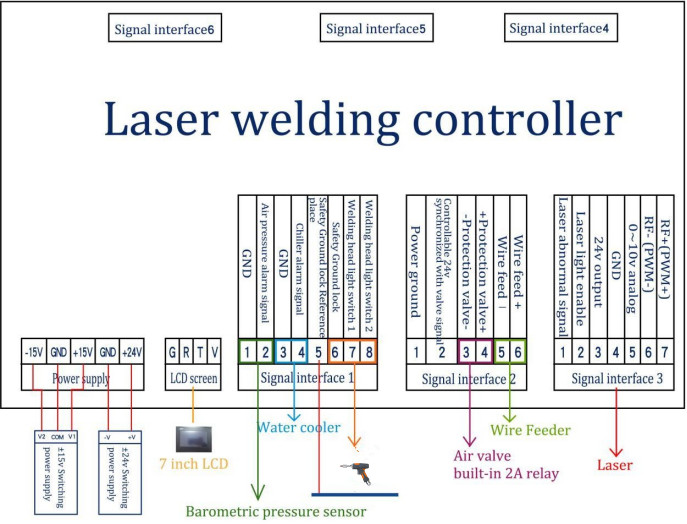

Incazelo yezintambo zesilawuli

Itheminali yokunikeza amandla isilawuli

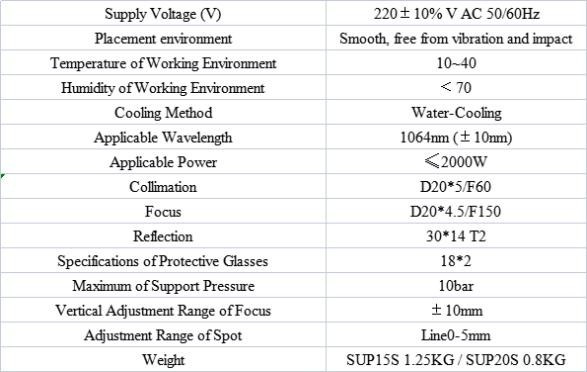

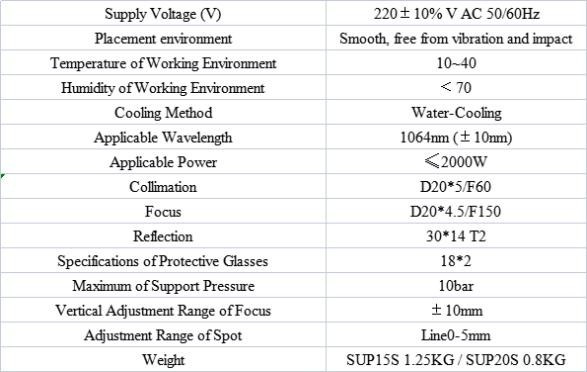

Ukunikezwa kwamandla kusebenzisa isixhumi esibonakalayo se-5P, futhi ugesi onikeziwe we-24V onikeziwe kanye nogesi oshintshwayo we-15V usetshenziselwa ukunikezwa kwamandla.

Sicela uqaphele ukuthi amandla okushintsha i-15V ahlukanisa izigxobo ezinhle nezingezinhle, i-V1 ixhunywe ku-15V+, i-V2 ixhunywe ku-15V-, futhi noma iyiphi i-COM ekunikezeni kwamandla okushintsha i-15V ixhunywe ku-pin 2 GND!

Sicela uqaphele ukuthi ukunikezwa kwamandla okushintshwa kufanele kumiswe!

Isilawuli LCD24/5000

Intambo ye-LCD ilethwa nedivayisi futhi ingaxhunywa ngokuqondile.Bheka umfanekiso ongenhla ukuze uthole izincazelo ezithile

Isilawuli LCD24/5000

Intambo ye-LCD ilethwa nedivayisi futhi ingaxhunywa ngokuqondile.Bheka umfanekiso ongenhla ukuze uthole izincazelo ezithile

Isixhumi esibonakalayo sesignali yesilawuli 1

①/②Iphinikhodi yokufaka isignali ye-alamu yomfutho womoya, uma udinga ukunika amandla (izintambo ezidingekayo), sicela usethe ileveli ye-alamu yomfutho womoya ngemuva ibe phezulu, ngaphandle kwalokho iphansi.

Iphinikhodi engu-③/④ iyisiginali ye-alamu yethangi lamanzi.Uma udinga ukuyivula (i-wiring iyadingeka), sicela usethe izinga le-alamu yomfutho womoya ngemuva libe phezulu, ngaphandle kwalokho liphansi.

⑤Iphinikhodi iyindawo eyireferensi yokukhiya phansi kokuphepha, futhi ixhunywe ngokuqondile kucwecwe lokusebenza ngocingo.

⑥ Cha. iphinikhodi wukhiye wesisekelo sokuphepha wekhanda lokushisela, elixhunywe entanjeni eluhlaza okwesibhakabhaka yocingo oluwumgogodla wesithathu, lapho ikhanda lokushisela lithinta ucezu lokusebenza, isikhiye sokuphepha sivuliwe ngalesi sikhathi.

⑦ Iphinikhodi yenombolo wukushintsha kwekhanda lokushisela, elixhunywe ocingweni olunsundu lwentambo yomgogodla emithathu.

⑧Iphinikhodi engu-switch switch yekhanda lokushisela, exhunywe entanjeni emnyama yocingo oluwumongo emithathu, lapho i-trigger idonswa, inkinobho yokucupha ivuliwe

Sicela uqaphele ukuthi kuphela uma ingekho i-alamu, futhi isignali yokukhiya okuphephile nenkinobho yokucupha ivuliwe, isignali yokuphumayo yembobo elandelayo izothunyelwa.

Isibonisi sesignali yesilawuli 2

Ukuphela kwe-2 yesixhumi esibonakalayo sesignali kusebenzisa isixhumi esibonakalayo esingu-6P, futhi i-valve yomoya ihlobene nokuphakelwa kwezintambo

①Izinyawo ezigodliwe

②Izinyawo ezigodliwe (zivumelaniswe nesignali yamaphini angu-4)

③/④Unyawo wukuphuma kwevalvu engu-24V, xhuma kuvalvu

⑤/⑥Iphinikhodi intambo yesiginali yesiphakeli socingo, imbobo yesignali yesiphakeli socingo, kungakhathaliseki ukuthi iphozithivu noma inegethivu

Isixhumi esibonakalayo sesignali yesilawuli 3

①Iphinikhodi yokufaka isiginali ye-alamu ye-laser +, uma udinga ukuyinika amandla, sicela usethe izinga le-alamu yomfutho womoya libe phezulu ngemuva.

②Iphinikhodi inikwe amandla+, xhuma ku-laser enable+

③Iphinikhodi ingu-24V okukhiphayo, ikhipha ngokuqondile okungu-24V+ ngemva kokuvula amandla

④Inombolo yesilwane esifuywayo siyindawo evamile (inkomba yezinyawo 1/2/3/5)

⑤Iphinikhodi iyinani le-analog + okukhiphayo, inani le-analog liyanikezwa

⑥Iphinikhodi isignali eshintshiwe ye-PWM

⑦ Iphinikhodi yenombolo yisignali yokushintshashintsha ye-PWM+

Umdwebo wezintambo zesilawuli

Qaphela: Itheminali ye-COM kagesi oshintshwayo ongu ±15V kanye netheminali -V (0V) yokushintshwa kwamandla kagesi +24V kufanele ixhunywe ku-GND futhi ixhunywe ngokugcwele kucezu lokusebenza ngesikhathi esifanayo.Igobolondo lamandla okushintshashintshayo kufanele lixhunywe phansi, ngaphandle kwalokho, i-alamu yokukhiya phansi kokuphepha ingase ivele, futhi akukho kukhanya okuzokhishwa.

I-Optical interface yokufaka

Ikhanda lokushisela le-SUP lilungele iningi lamajeneretha e-laser yezimboni.Izixhumi ezisetshenziswa kakhulu ze-fiber optical zifaka i-IPG, i-Ruike, i-Chuangxin, i-Fibo, i-Tottenham, i-Jept, i-Kaplin, njll. Ama-opticals kufanele agcinwe ehlanzekile futhi lonke uthuli kufanele lususwe ngaphambi kokusetshenziswa.

Uma i-fiber ifakiwe, ikhanda lokusika kufanele lijikelezwe ngamadigri angu-90 ukuze libe ne-horizontal, bese i-fiber isetshenziselwa ukuvimbela uthuli ukuthi lungangeni ku-interface.

indlela yokufaka (ama-Applets)

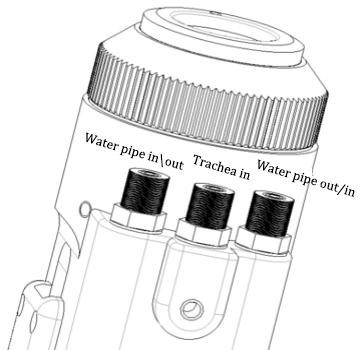

Ukuvikela igesi ne-water chiller interface

Ipayipi lamanzi kanye nesixhumi esibonakalayo sepayipi lomoya kungafakwa ngamapayipi anobubanzi obungaphandle obuyi-6MM kanye nobubanzi bangaphakathi obuyi-4MM.Indlela yomoya ingena phakathi nendawo, futhi izinhlangothi ezimbili amapayipi okungena Amanzi kanye nokuphumayo (kungakhathalekile ukuthi ikuphi nendawo yokuphuma nokuphumayo) , Njengoba kuboniswe ngezansi:

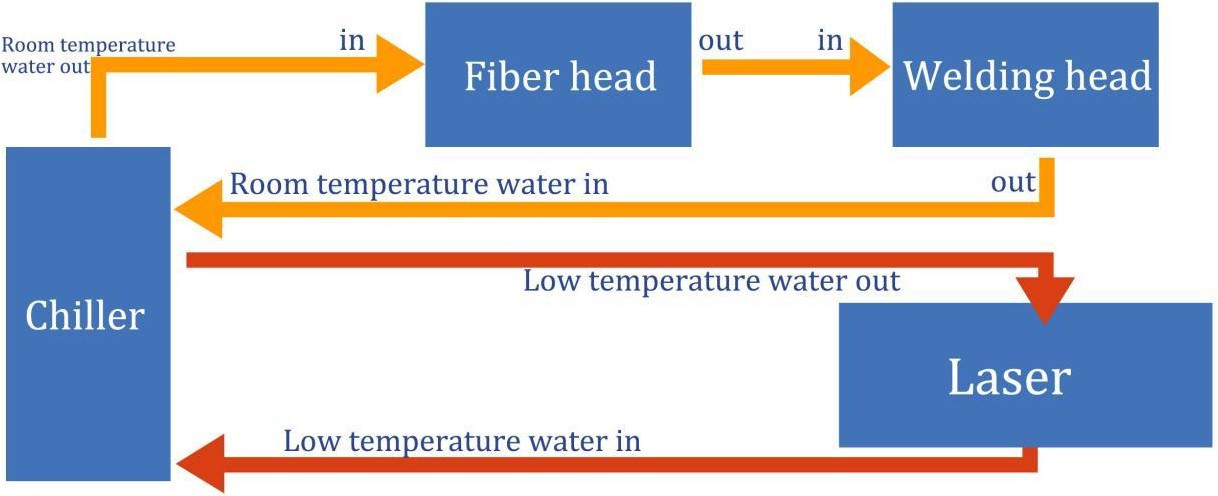

Uhlelo lokupholisa luhlukaniswe ingxenye yesifunda samanzi sekhanda le-welding kanye nengxenye yesifunda samanzi yekhanda le-fiber optical, elixhunywe ochungechungeni, njengoba kuboniswe esithombeni esingezansi:

Isixhumi esibonakalayo sokuxhuma isibhamu sokushisela kanye nebhokisi lokulawula

Isibhamu esishiselayo kanye nebhokisi lokulawula zisebenzisa izintambo ezintathu ukuxhuma, okuhlanganisa: intambo yamandla enjini enezisekelo ezimbili, ulayini wesiginali yemoto enezinhlaka ezinhlanu, ukhiye wokuphepha owumgogodla wesithathu nolayini wenkinobho yokucupha.

Izintambo zamandla enjini/amasignali (izintambo ezimbili ezimnyama) zixhunywe ngqo engxenyeni yenjini yekhanda lokushisela futhi zingahlakazwa (izinketho ezimbili ziyatholakala: 1. Vula ikhava yemoto kanye nepuleti elisemaceleni lesibhamu esibanjwa ngesandla 2. Vula ibhokisi lokulawula Wonke amapulaki)

Inkinobho yokukhiya nenkinobho yokucupha isetshenziswe izintambo ezintathu eziyinhloko ezisetshenzisiwe Ipulaki yendiza ekhiphekayo:Izintambo zokukhiya ngokuphephile nezinkinobho, ezi-1 ziluhlaza okwesibhakabhaka, ezi-2 zimnyama, futhi ezi-3 zinsundu (ixhunywe kuphinikhodi engu-6/7/8 yesixhumi esibonakalayo 1, bona incazelo yezintambo zebhokisi lokulawula elingenhla ukuze uthole imininingwane)

Ukufakwa kwe-wire feeder

Ipulaki yasemoyeni enezisekelo ezimbili emsileni wesiphakeli socingo ixhunywe kuphinikhodi engu-5/6 yesibonisi esibonakalayo 2. Bheka okulandelayo ukuze uthole indlela ethile yokufaka.

Chofoza: Imiyalo Yokufaka Isiphakeli Socingo(Applets)

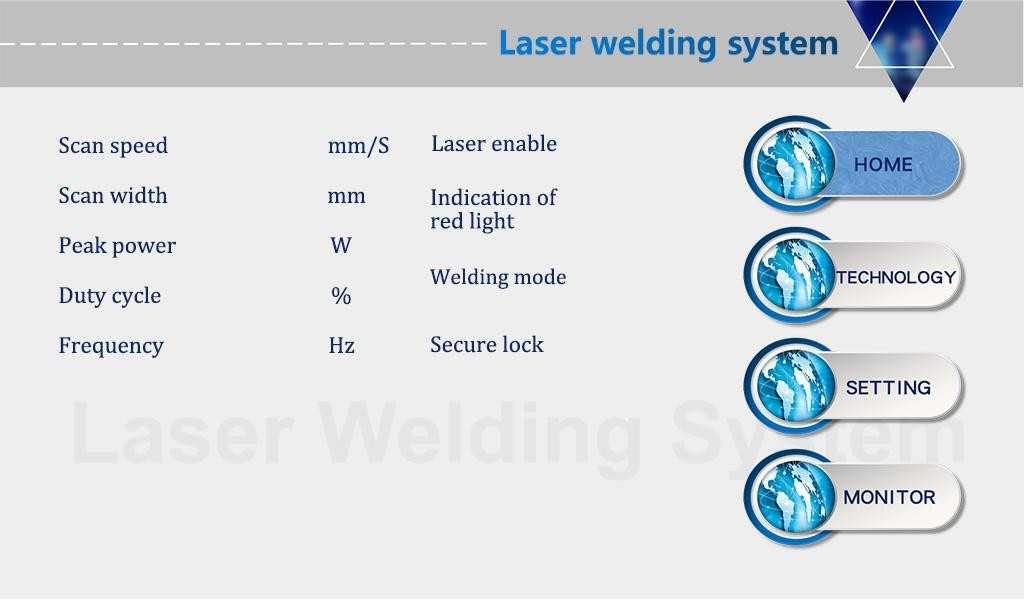

Iphaneli yokulawula kanye nomhlahlandlela wokusebenza (okulandelayo yinguqulo ye-V3.3)

Isifinyezo sokusebenza kanye nomhlahlandlela wokusebenza

Iphaneli yokusebenza yochungechunge lwe-SUP ikakhulukazi yakhiwe isikrini sokuthinta kanye nebhokisi lokulawula.

Thinta ikhasi eliyinhloko, inqubo, ukusetha, nokuqapha isixhumi esibonakalayo sokusebenza.

Isikrini esikhulu sokusebenza kwesikrini sokuthinta

①Kulesi sikhombimsebenzisi, ungabona amapharamitha enqubo yamanje kanye nolwazi lwe-alamu esheshayo.

②I-laser ivuliwe futhi isibani esibomvu senkomba IVULIWE uma sivuliwe.

③Ilokhi yokuphepha ivamise ukuba mpunga, futhi uma ikhanda lokushisela lithinta ucezu lokusebenza, liba luhlaza futhi lingacutshungulwa.

④ Ukukhetha imodi yokushisela, okuzenzakalelayo kuyaqhubeka.Uma isethwe ukuthi ibone ukushisela, ingakhipha ukukhanya ngezikhathi ezithile ukuze isebenze endaweni, okuyinto elula ukulawula isikhathi sokushisela ngenxa yephutha lomuntu.Lo msebenzi udinga ukusethwa njengoba kudingeka (inguqulo ye-V3.3 iwumsebenzi ongenhla)

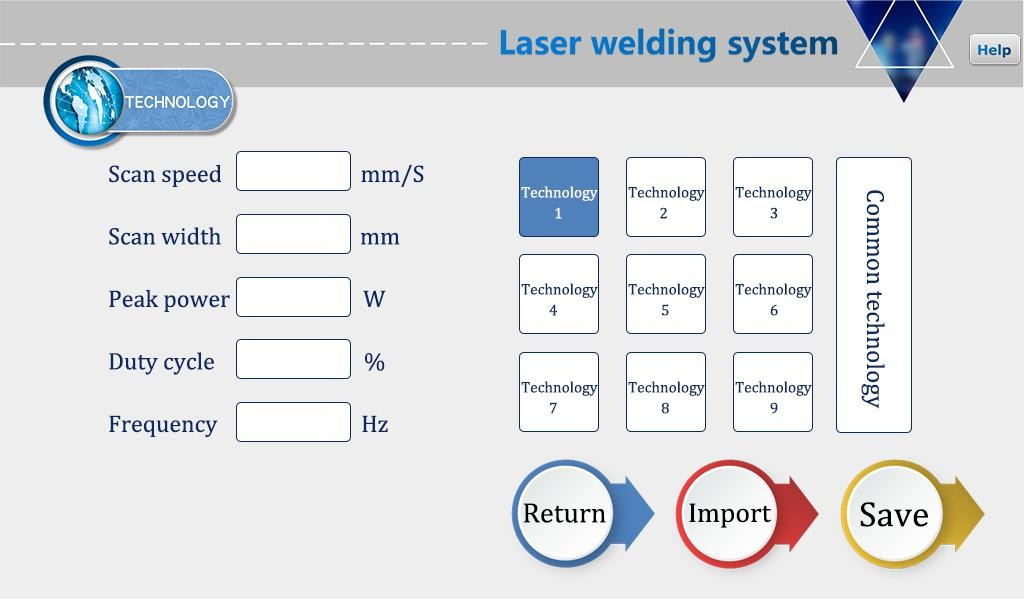

Isikrini esikhulu sokusebenza kwenqubo

①Isixhumi esibonakalayo senqubo siqukethe izinhlaka zenqubo zokulungisa iphutha, ezingashintshwa ngokuchofoza ibhokisi.Ngemuva kokuthi ukuguqulwa kuqediwe, chofoza okuthi KULUNGILE, bese ukugcine enqubweni yesinqamuleli.Uma uyisebenzisa, chofoza okuthi Ngenisa (Guqula-Londoloza-Ngenisa).

②Ibanga lesivinini sokuskena lingu-2-6000mm/S, futhi ububanzi bokuskena bungu-0^5mm.Isivinini sokuskena sinqunyelwe ububanzi bokuskena.Ubudlelwano bomkhawulo buthi: 10≤isivinini sokuskena/(ububanzi bokuskena*2) ≤1000 Uma lweqa umkhawulo, luzoba inani lomkhawulo ngokuzenzakalelayo.Uma ububanzi bokuskena busethelwe ku-0, ngeke buskene (okungukuthi umthombo wokukhanya wephoyinti) (isivinini sokuskena esisetshenziswa kakhulu: 300mm/S, ububanzi 2.5mm).

③Amandla aphezulu kumele abe ngaphansi noma alingane namandla e-laser ekhasini lepharamitha (isibonelo, amandla e-laser angu-1000W, lapho ke inani alikho ngaphezu

1000).

④Ibanga lesilinganiso somsebenzi 0~100 (okuzenzakalelayo 100, ngokuvamile akudingekile ukushintsha).

⑤Ibanga lokuvama kwe-pulse elinconyiwe ngu-5-5000Hz (okuzenzakalelayo ngu-2000, ngokuvamile akudingi ukushintshwa).

⑥Chofoza inkinobho ethi USIZO phezulu kwesokudla ukuze uthole izincazelo eziningi ezihlobene nepharamitha.

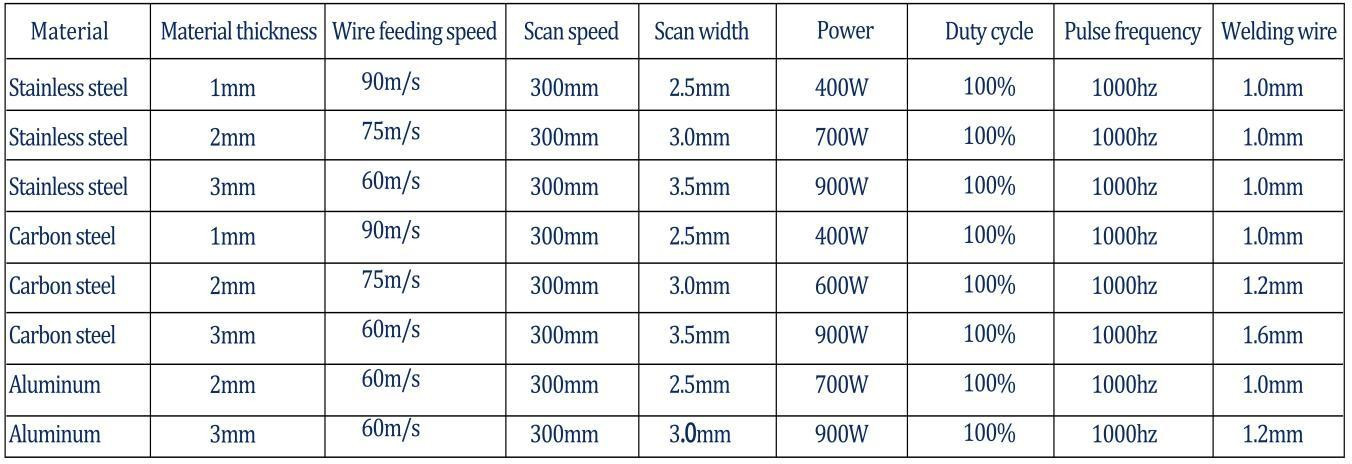

Ireferensi yenqubo (ngokuya ngezimo zangempela, okulandelayo okokubhekisela kuphela)

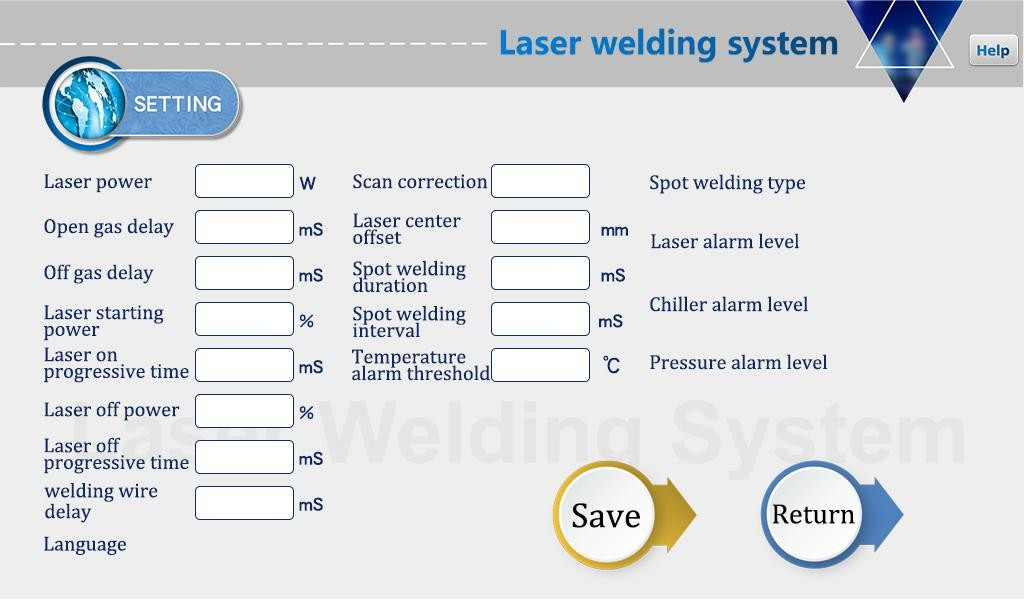

Setha isikrini esikhulu sokusebenza

Inombolo yepholisi: 123456

①Amandla e-laser amandla amakhulu we-laser asetshenzisiwe.

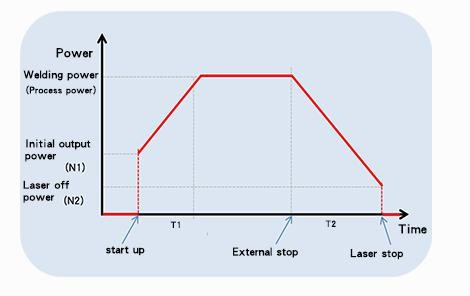

②Ukulibaziseka komoya okushintshayo kuzenzakalela kube ngu-200ms, futhi ububanzi bungu-200ms-3000ms.

③Uma ukukhanya kuvuliwe, kuzokhuphuka kancane kancane ukusuka ku-N1% wamandla enqubo kuye ku-100%;lapho ukukhanya kucishiwe, kuzokhula kancane kancane kusuka ku-100% wamandla enqubo.

Ku-N2;(njengoba kukhonjisiwe emfanekisweni ongezansi).

④Isinxephezelo sokulibaziseka kokuphakelayo ngocingo yisikhathi sangaphambi kwesikhathi sokuphakelwa kwentambo ngokuhlobene nesignali yokukhanya, engasetshenziswa ngokuhambisana nomsebenzi wokuhoxa.

⑤Umkhawulo we-alamu wezinga lokushisa eliphezulu ngu-70℃.Uma inani lisethelwe ku-0, i-alamu yezinga lokushisa ngeke ibonwe.

⑥Skena ububanzi be-coefficient yokulungisa engu-0.01~4, ububanzi bomugqa wethagethi ye-coefficient/ububanzi bomugqa wokulinganisa: ngokuvamile buyi-1.25.

⑦Laser center offset -3~3mm, yehlise bese uyihambisa kwesokunxele, yikhulise bese uyihambisa kwesokudla.

⑧Isiginali yezinga le-alamu iyona ezenzakalelayo, futhi i-alamu evikelekile ingashintshwa ngokuqondile ukuze ithole izinga elihambisanayo.

⑨Ubude besikhathi sokushisela i-Spot isikhathi sokukhipha ukukhanya ngemva kokudonsa i-trigger, okusho ukuthi, noma inkinobho ikhishiwe, ukukhanya kusazokhishwa ngokuvumelana nesikhathi esichithiwe (inguqulo ye-V3.3 iwumsebenzi ongenhla)

⑩Isikhathi sekhefu le-Spot welding isikhathi sokukhanya sokuma phakathi kokushisela kwamabala amabili ngemva kokudonsa inkinobho yokuqalisa (inguqulo ye-V3.3 nangaphezulu)

⑧Chofoza inkinobho ethi USIZO phezulu kwesokudla ukuze uthole incazelo ehlobene nepharamitha.

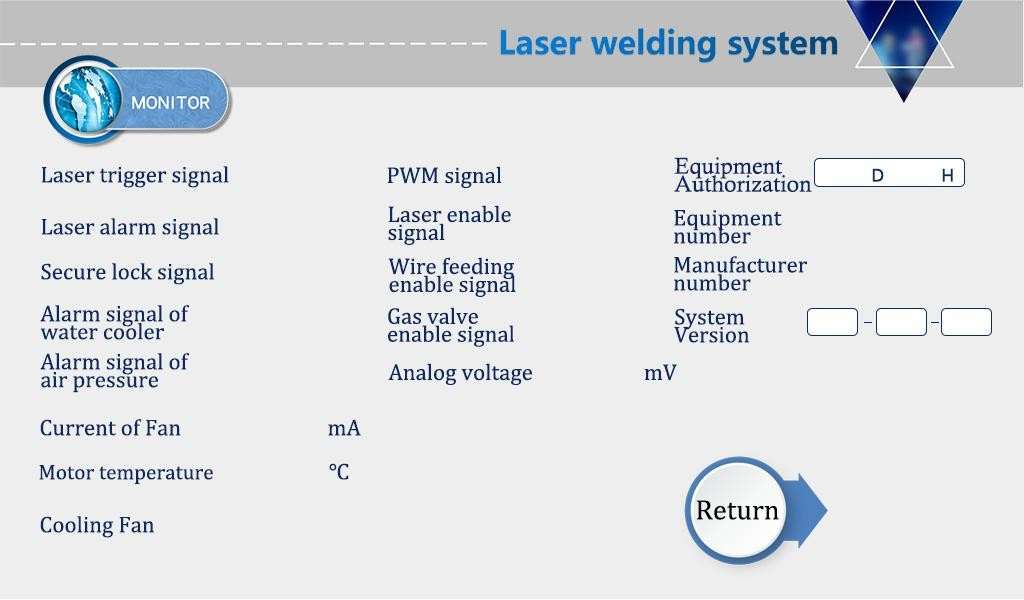

Ukuqapha interface main

Lesi sixhumanisi sibonisa isimo sesignali yokuthola ngayinye nolwazi lwedivayisi

Chofoza ekugunyazweni kwedivayisi ukuze ufake isixhumi esibonakalayo sesikhathi sokusebenzisa esigunyaziwe, ngemuva kokufaka iphasiwedi, isistimu ingagunyazwa isikhathi sokusebenzisa.

Izindlela zokubethela zokugunyazwa nezindlela zokukhipha ukubethela ziyefana:

I-system decryption metho (i-Apple)Iphasi yokushisela ebanzi, ukungena okuphezulu.

Isikrini sokuthinta, futhi usekele ukuphakelwa kwentambo eyodwa kanye nokuphakelwa kwezintambo ezimbili