isibhamu esiphathwa ngesandla se-laer

isibhamu esiphathwa ngesandla se-laer welding,

umkhiqizi wesibhamu we-laser welding, laser welding head factory, laser Welding imikhiqizo, ODM laser welding ikhanda, OEM laser Welding ikhanda, I-wholesale laser Welding umkhiqizo,

Ukuphepha – Ukuphepha

Isistimu yokubona ukuphepha ethuthukisiwe enama-alamu amaningana okuphepha asethiwe, aphephile futhi azinzile

Ukonga isikhathi – kuyasebenza futhi kuyasiza

Isibuko esigxilile nekhabethe lesibuko elivikelayo, kulula ukulishintsha

I-lightweight —— ilula futhi incane umthwalo

Usayizi omncane, isisindo esilula, ukusebenza okuguquguqukayo, kulula ukuyisebenzisa

Ikhwalithi - ukusebenza okuhle okuzinzile kwe-welding

Amandla e-welding aphezulu, i-deformation encane, ukujula kokuncibilika okuphezulu

Ukusebenza - imisebenzi eminingi

Sekela ukushisela okubanjwa ngesandla okuqhubekayo, ukushisela indawo, ukuhlanza, ukusika, “isandla” “kusuka” – umzimba, ukugunyazwa kwephasiwedi

Sizibophezele ekulawuleni ikhwalithi okuqinile kanye nenkonzo yamakhasimende ecabangelayo, futhi abasebenzi bethu abanolwazi bazoxoxa nawe ngezimfuneko zakho noma nini.Umthamo wangempela wokukhiqiza wenkampani wonyaka udlula amayunithi angama-20,000, futhi umthamo wokukhiqiza omkhulu wonyaka ungafinyelela kumayunithi angaphezu kuka-30,000.Imikhiqizo yethu ithengiswa kahle kuwo wonke amadolobha nezifundazwe kulo lonke elaseShayina, futhi ithunyelwa kumakhasimende ase-European Union nakwamanye amazwe nezifunda.

Ngesikhathi esifanayo, samukela futhi ama-oda we-OEM ne-ODM.Ngethemba ukuthi singaba ozakwethu abasondelene nabahlala isikhathi eside!

I-1) Qinisekisa ukusekela okuthembekile ngaphambi kokunikezwa kwamandla.

2) Inhloko yokukhipha i-laser ixhunywe ekhanda le-solder.Sicela uhlole ikhanda elikhipha i-laser ngokucophelela ukuze uvimbele uthuli noma okunye ukungcola lapho usebenzisa.Lapho uhlanza ikhanda eliphumayo le-laser, sicela usebenzise iphepha lelensi elikhethekile.

3) Uma okokusebenza kungasetshenziswa ngokuhambisana nendlela eshiwo kule ncwajana, kungahle konakaliswe ngokushiya okokusebenza kusesimweni esingejwayelekile sokusebenza.

4) Uma ushintsha ilensi yokuzivikela, sicela unakekele ukuvikela.

5) Sicela uqaphele: Uma usebenzisa idivayisi okokuqala, lapho ukukhanya okubomvu kungakwazi ukukhishwa embotsheni yethusi, sicela uqaphele ukuthi ungakhanyi.

Imininingwane yokulethwa kwephakheji yekhanda lokushisela elibanjwa ngesandla

★Isendlalelo sokuqala

Ikhanda le-SUP20S lokushisela i-1pc

Isethi yesistimu 1

Ikhebula lesistimu lisezingeni elingu-10m

★Isendlalelo sesibili

Umbhobho wethusi 7pcs Cutting nozzle 1pc

Isikali tube 1pc

Isibuko sokuvikela 10pcs

Isiqeshana se-Grounding 1pc

Ikhebuli yokuxhuma isikrini 1m

Bonisa isethi engu-1

★Isendlalelo sesithathu

Bonisa isikrini 1pcs

Ukushintsha amandla 2pcs

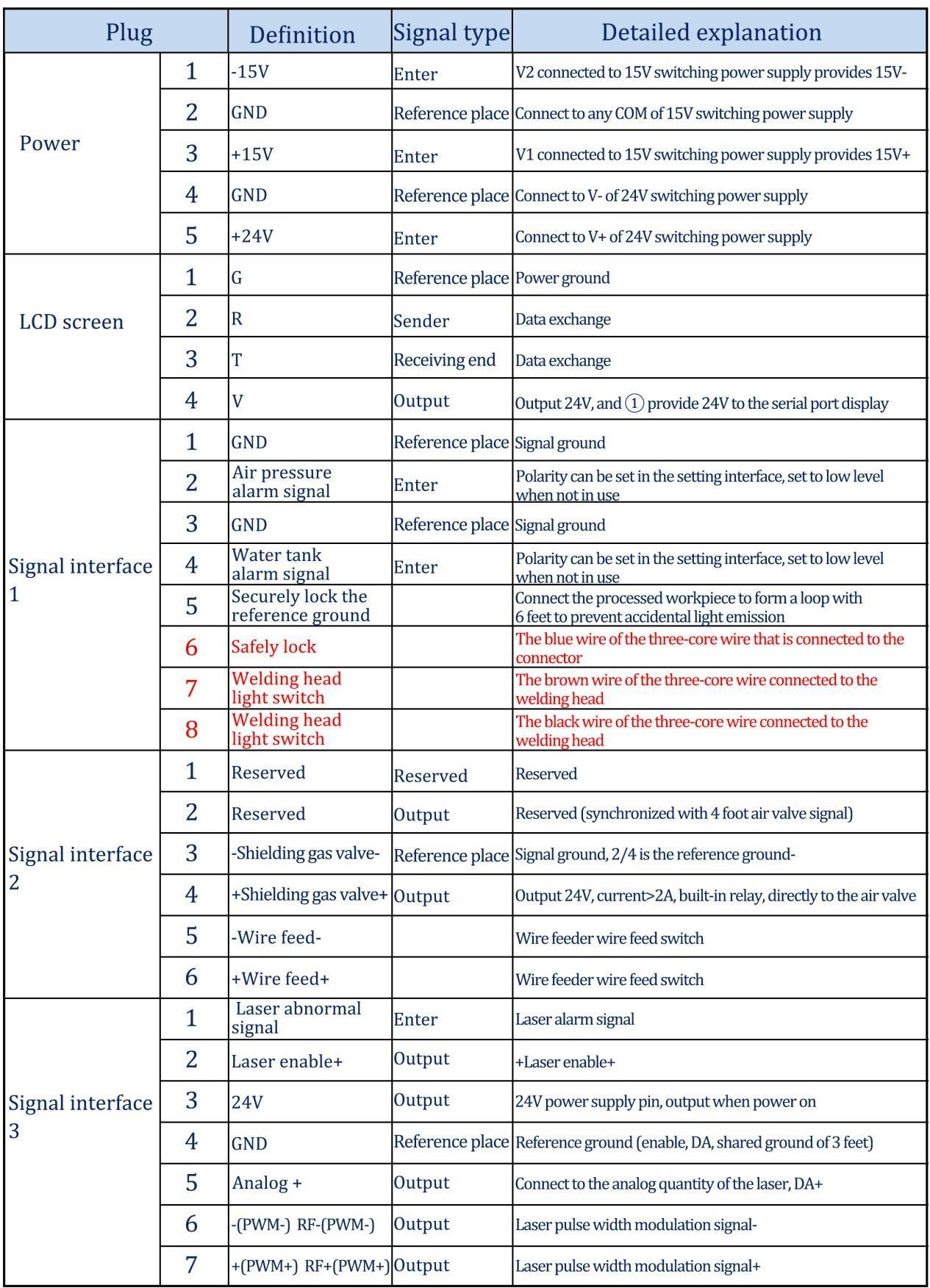

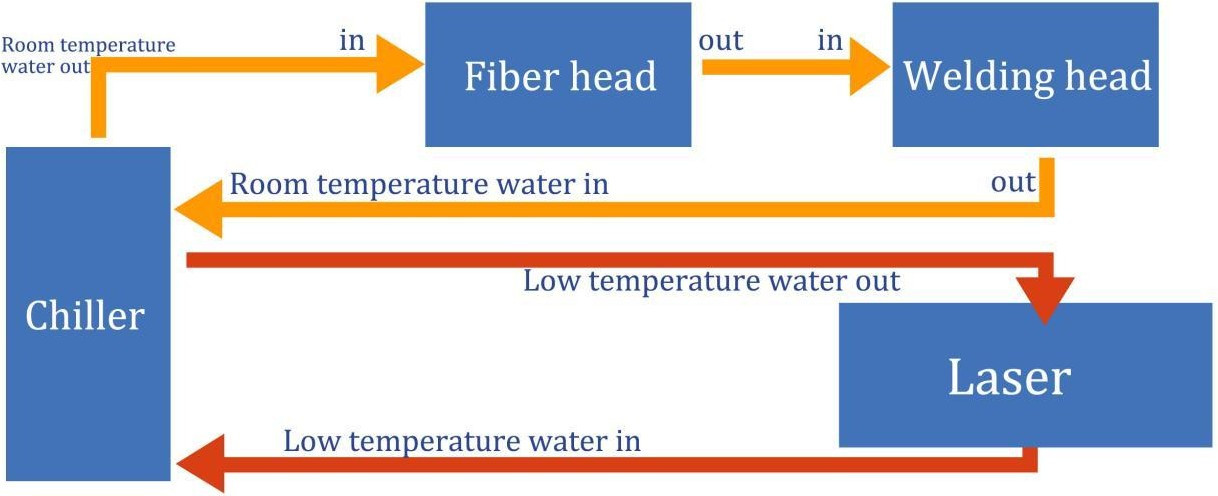

Incazelo yezintambo zesilawuli

Itheminali yokunikeza amandla isilawuli

Ukunikezwa kwamandla kusebenzisa isixhumi esingu-5P futhi kunikwe amandla kusetshenziswa ukunikezwa kwamandla okushintshwa kwe-24V kanye nokunikezwa kwamandla okushintsha okungu-15V okunikeziwe.

Sicela uqaphele ukuthi amandla okushintsha i-15V ahlukanisa phakathi kokuhle nokubi, i-V1 ixhumeke ku-15V+, i-V2 ixhunywe ku-15V-, futhi noma iyiphi i-COM ekushintsheni kuka-15V ugesi ixhunywe ku-pin 2 GND!

Sicela uqaphele ukuthi ukunikezwa kwamandla okushintshwa kufanele kumiswe!

Isilawuli LCD24/5000

Intambo ye-LCD ilethwa nedivayisi futhi ingaxhunywa ngokuqondile.Bheka umfanekiso ongenhla ukuze uthole izincazelo ezithile

Isixhumi esibonakalayo sesignali yesilawuli 1

①/②Iphinikhodi yokufaka isignali ye-alamu yomfutho womoya, uma udinga ukunika amandla (izintambo ezidingekayo), sicela usethe ileveli ye-alamu yomfutho womoya ngemuva ibe phezulu, ngaphandle kwalokho iphansi.

Iphinikhodi ③/④ wukufaka kwe-alamu yethangi lamanzi.Uma udinga ukuyinika amandla (i-wiring edingekayo), setha ileveli ye-alamu yomfutho womoya ibe phezulu ngemuva, ngaphandle kwalokho iphansi.

Iphinikhodi yenombolo iyindawo eyireferensi yesikhiya saphansi sokuphepha futhi ixhunywe ngentambo ngqo kucezu lomsebenzi wenqubo.

Iphinikhodi iyisikhiya sesisekelo sokuphepha sekhanda lokushisela, elixhunywe ocingweni oluluhlaza okwesibhakabhaka lwezintambo eziwumgogodla ezintathu, lapho ikhanda lokushisela lithinta ucezu lokusebenza, ilokhi yokuphepha ivuliwe ngalesi sikhathi.

I-Pin No. iyiswishi yokuvula/yokuvala yekhanda lokushisela, exhunywe entanjeni ensundu yentambo yamacore amathathu.

I-Pin No. iwukushintsha kokukhanya kwekhanda lokushisela, elixhunywe kwintambo emnyama yocingo olunamacore amathathu, lapho i-trigger idonswa, inkinobho yokucupha iyakhanya.

Sicela uqaphele ukuthi isignali yokuphumayo yezimbobo ezilandelayo izothunyelwa kuphela uma ingekho i-alamu futhi isignali yokukhiya ukuphepha nenkinobho yokucupha ivuliwe.

Isibonisi sesignali yesilawuli 2

I-interface yesignali 2 ekupheleni isebenzisa isikhombimsebenzisi se-6P, kanye nomugqa ongenayo ohlobene ne-valve yomoya

① Unyawo olugodliwe

② iphinikhodi egodliwe (ivunyelaniswe nesignali yamaphini angu-4)

③/④ iphinikhodi ingu-24V ophumayo wevalvu yomoya, exhunywe kuvalvu yomoya

⑤/⑥ unyawo ulayini wesignali wesiphakeli socingo, okuyimbobo yesignali yesiphakeli socingo, futhi asihlukaniswanga sibe sinhle nesibi.

Umdwebo wezintambo zesilawuli

①/②Iphinikhodi yokufaka isignali ye-alamu yomfutho womoya, uma udinga ukunika amandla (izintambo ezidingekayo), sicela usethe ileveli ye-alamu yomfutho womoya ngemuva ibe phezulu, ngaphandle kwalokho iphansi.

Iphinikhodi ③/④ wukufaka kwe-alamu yethangi lamanzi.Uma udinga ukuyinika amandla (i-wiring edingekayo), setha ileveli ye-alamu yomfutho womoya ibe phezulu ngemuva, ngaphandle kwalokho iphansi.

Iphinikhodi yenombolo iyindawo eyireferensi yesikhiya saphansi sokuphepha futhi ixhunywe ngentambo ngqo kucezu lomsebenzi wenqubo.

Iphinikhodi iyisikhiya sesisekelo sokuphepha sekhanda lokushisela, elixhunywe ocingweni oluluhlaza okwesibhakabhaka lwezintambo eziwumgogodla ezintathu, lapho ikhanda lokushisela lithinta ucezu lokusebenza, ilokhi yokuphepha ivuliwe ngalesi sikhathi.

I-Pin No. iyiswishi yokuvula/yokuvala yekhanda lokushisela, exhunywe entanjeni ensundu yentambo yamacore amathathu.

I-Pin No. iwukushintsha kokukhanya kwekhanda lokushisela, elixhunywe kwintambo emnyama yocingo olunamacore amathathu, lapho i-trigger idonswa, inkinobho yokucupha iyakhanya.

Sicela uqaphele ukuthi isignali yokuphumayo yezimbobo ezilandelayo izothunyelwa kuphela uma ingekho i-alamu futhi isignali yokukhiya ukuphepha nenkinobho yokucupha ivuliwe.

Isibonisi sesignali yesilawuli 2

I-interface yesignali 2 ekupheleni isebenzisa isikhombimsebenzisi se-6P, kanye nomugqa ongenayo ohlobene ne-valve yomoya

① Unyawo olugodliwe

② iphinikhodi egodliwe (ivunyelaniswe nesignali yamaphini angu-4)

③/④ iphinikhodi ingu-24V ophumayo wevalvu yomoya, exhunywe kuvalvu yomoya

⑤/⑥ unyawo ulayini wesignali wesiphakeli socingo, okuyimbobo yesignali yesiphakeli socingo, futhi asihlukaniswanga sibe sinhle nesibi.

Isixhumi esibonakalayo sesignali yesilawuli 3

Iphinikhodi okokufaka kwesiginali ye-alamu ye-laser +, uma ufuna ukunika amandla, sicela usethe izinga le-alamu yomfutho womoya libe sezingeni eliphezulu ngemuva.

Iphinikhodi inika amandla+, xhuma i-laser enable+.

Iphinikhodi engu-3 ingu-24V okukhiphayo, okukhiphayo okungu-24V+ ngokuqondile ngemva kokuvula amandla

Iphinikhodi ④ iyindawo evamile (inkomba yephinikhodi 1/2/3/5)

I-Pin No. i-analog + okukhiphayo, i-analog inikezwa

Iphinikhodi inombolo isignali yokushintshashintsha ye-PWM

Iphinikhodi yedijithali iyisiginali eshintshayo ye-PWM+ ⑦ Iphinikhodi yedijithali iyisiginali eshintshayo ye-PWM+

Umdwebo wezintambo zesilawuli

Qaphela: Itheminali ye-COM ye-±15V switching power supply kanye netheminali -V (0V) ye-+24V switching power supply kufanele ixhunywe ku-GND futhi ixhunywe ngokugcwele kucezu lokusebenza ngesikhathi esifanayo.Icala lokushintshwa kwamandla kagesi kufanele lixhunywe phansi, ngaphandle kwalokho i-alamu yaphansi yokukhiya ukuphepha ingase yenzeke futhi ngeke ikhanyise.

I-Optical interface yokufaka

Amakhanda we-SUP welding ayatholakala kumajeneretha amaningi we-laser yezimboni.Izixhumi ezibonakalayo ze-fiber optic ezivame ukusetshenziswa yi-IPG, i-RICO, i-Troncin, i-FIBO, i-Tottenham, i-Jephte, i-Caplin, njll. I-optics kumele igcinwe ihlanzekile futhi isuswe kulo lonke uthuli ngaphambi kokusetshenziswa.

Uma ufaka i-fiber, ikhanda lokusika kufanele lijikelezwe ngamadigri angu-90 ukuze livundlile ngaphambi kokusebenzisa i-fiber ukuvimbela uthuli ukuthi lungangeni esibonakalayo.

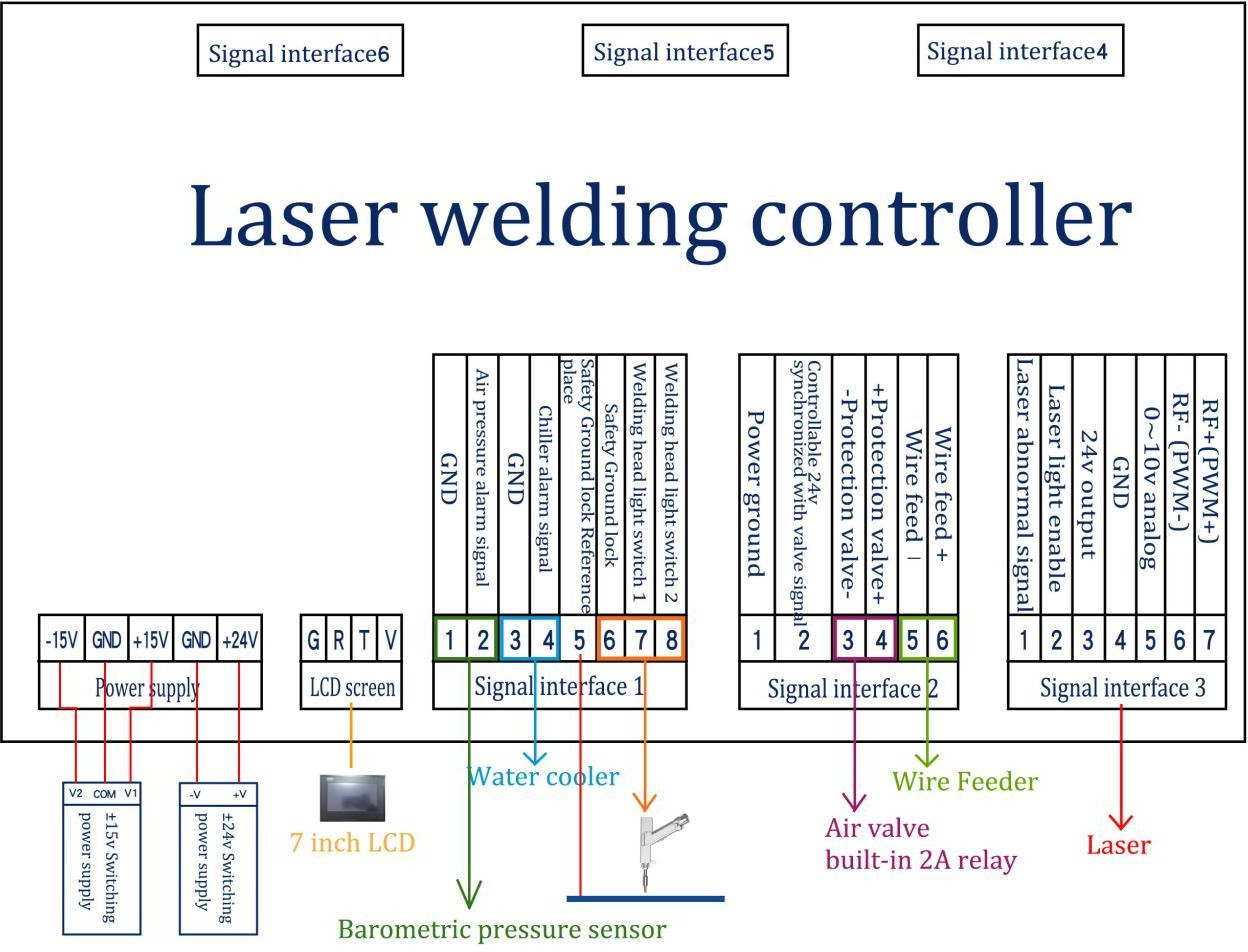

Ukuvikela igesi ne-water chiller interface

Isixhumi esibonakalayo sepayipi lamanzi negesi lingafakwa ngedayamitha yangaphandle engu-6MM nepayipi elingaphakathi elingu-4MM.Umzila wegesi ungena usuka phakathi nendawo, futhi amapayipi okungena kwamanzi kanye ne-outlet asezinhlangothini zombili (ngaphandle kokucabangela isiqondiso sokungena kwamanzi nokuphuma), njengoba kuboniswe ngezansi.

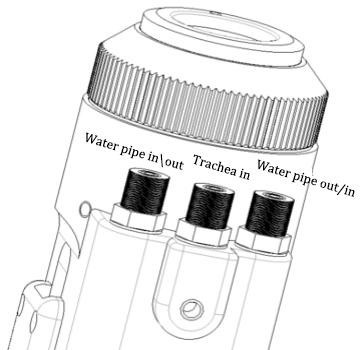

Uhlelo lokupholisa luhlukaniswe ingxenye yesifunda samanzi sekhanda le-welding kanye nengxenye yesifunda samanzi yekhanda le-fiber optical, elixhunywe ochungechungeni, njengoba kuboniswe esithombeni esingezansi:

Isibhamu esishiselayo nesixhumi esibonakalayo sokuxhumana sebhokisi

Isixhumanisi esibonakalayo se-welding gun nebhokisi lokulawula

Isibhamu esishiselayo sixhunywe ebhokisini lokulawula elinezintambo ezintathu, okuhlanganisa: intambo yamandla enjini enezisekelo ezimbili, intambo yesiginali yenjini enezisekelo ezinhlanu, isikhiya sokuphepha esinendawo eyodwa esinezingxenye ezintathu kanye nentambo yenkinobho yokucupha.

Izintambo zamandla enjini/amasignali (izintambo ezimbili ezimnyama) zixhunywe ngqo engxenyeni yemoto yekhanda lokushisela futhi zingasuswa (izinketho ezimbili: 1. Vula ikhava yemoto kanye nephaneli eseceleni yethoshi ephathwayo 2. Vula ibhokisi lokulawula Kokubili zixhunyiwe)

Inkinobho yokukhiya ukuphepha kanye nenkinobho yokucupha izintambo ezintathu eziyinhloko ezisetshenzisiwe Ipulaki yendiza ekhishwayo: isikhiya sokuphepha nentambo yezinkinobho, okuthi 1 kwakho kuluhlaza okwesibhakabhaka, 2 kumnyama, 3 kube nsundu (kuxhunywe kusixhumi esibonakalayo sesignali 1 pin 6/7/8, bona incazelo yezintambo zebhokisi lokulawula elingenhla).

Ukufakwa kwe-wire feeder

Ipulaki yendiza enezingqikithi ezimbili ekugcineni kwesiphakeli socingo ixhunywe kuphinikhodi engu-5/6 yesixhumi esibonakalayo 2. Sicela ubhekisele kokulandelayo ukuze uthole indlela ethile yokufaka.

Chofoza.Imiyalo yokufaka isiphakeli ngocingo (ama-Applets).

Iphaneli yokulawula kanye negayidi yokusebenza (inguqulo ye-V3.3 ngezansi).

Isifinyezo sokusebenza kanye nomhlahlandlela wokusebenza

Iphaneli yokusebenza yochungechunge lwe-SUP ikakhulukazi iqukethe isikrini sokuthinta kanye nebhokisi lokulawula.

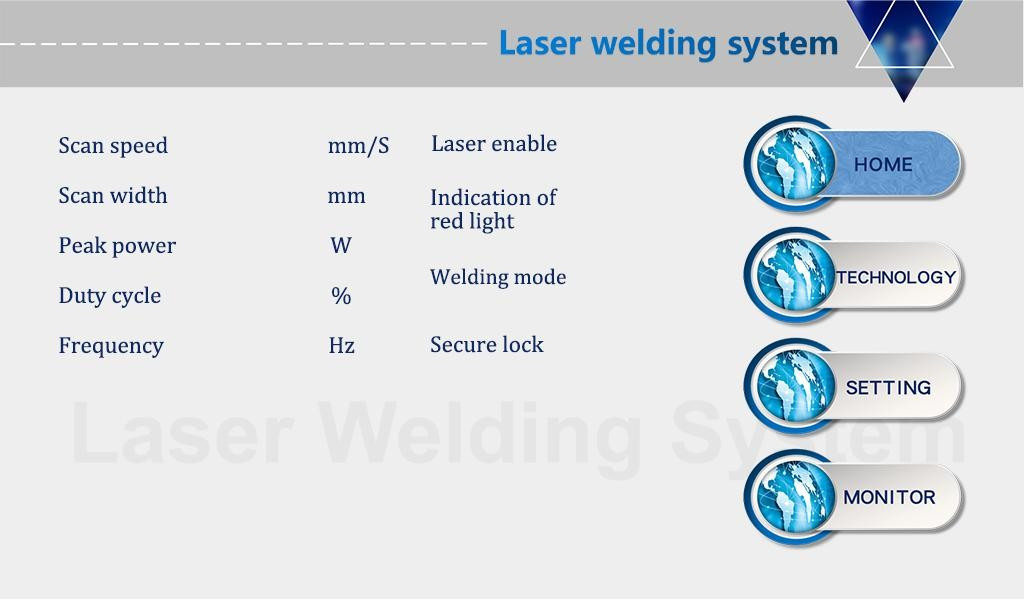

Thinta ikhasi eliyinhloko, inqubo, ukusetha, ukuqapha nezinye izikrini zokusebenza.

Isikrini esikhulu sokusebenza kwesikrini sokuthinta

①Kulesi sikrini, ungabona amapharamitha enqubo yamanje kanye nolwazi lwe-alamu esheshayo.

②I-laser inikwe amandla futhi isibani senkomba sibomvu uma sivuliwe.

③Ilokhi yokuphepha ivamise ukuba mpunga futhi iba luhlaza uma ikhanda lokushisela lithinta ucezu lokusebenza futhi inqubo ingenziwa.

④Imodi yokushisela ikhethiwe, futhi okuzenzakalelayo kuyaqhubeka.Uma isethwe ukuze ibone ukushisela, ingakhanya ngezikhathi ezithile ukuze isebenze, okulula ukulawula isikhathi sokushisela ngenxa yephutha lomuntu.Lo msebenzi udinga ukusethwa njengoba kudingeka (inguqulo ye-V3.3 yomsebenzi ongenhla)

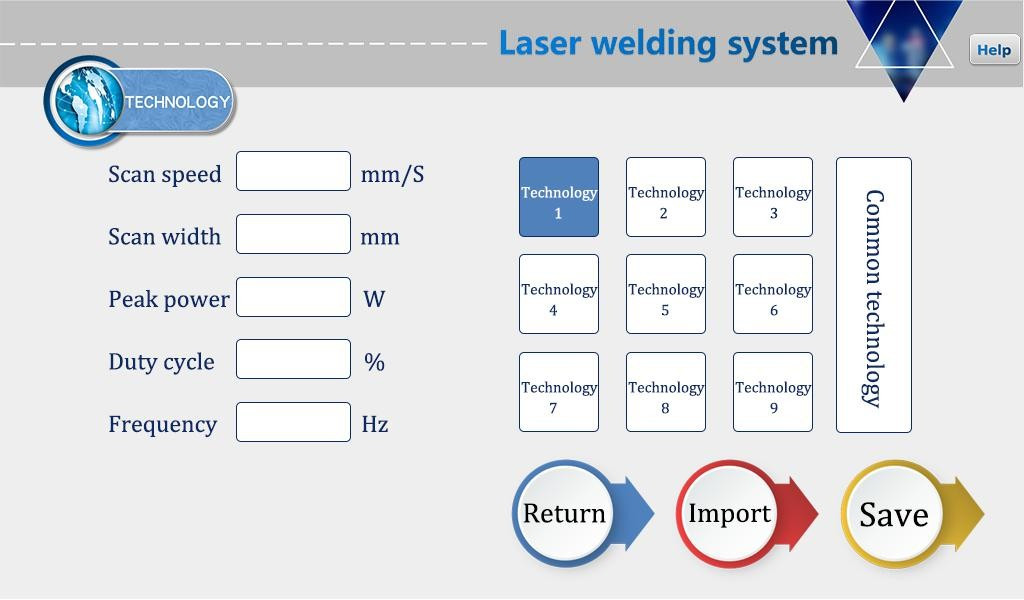

Isikrini esikhulu sokusebenza kwenqubo

①Isikrini senqubo siqukethe izinhlaka zenqubo zokulungisa iphutha, ezingashintshwa ngokuchofoza ibhokisi.Ngemva kokuqeda ukulungisa, chofoza okuthi KULUNGILE bese ukulondoloze kokuthi Inqubo Esheshayo.Ukusebenzisa, chofoza Ngenisa (Shintsha - Gcina - Ngenisa).

②Ibanga lesivinini sokuskena lingu-2-6000mm/S futhi ububanzi bokuskena bungu-0^5mm.Isivinini sokuskena sinqunyelwe ububanzi bokuskena.Ubudlelwano bomkhawulo bu.10≤ isivinini sokuskena/(skena ububanzi*2)≤1000 Uma umkhawulo weqiwe, kuzoba inani lomkhawulo ngokuzenzakalelayo.Uma ububanzi beskena busethelwe ku-0, ngeke kube khona ukuskena (okungukuthi umthombo wephoyinti) (isivinini sokuskena esivame kakhulu: 300mm/S, ububanzi 2.5mm).

Amandla aphezulu kufanele abe ngaphansi noma alingane namandla e-laser ekhasini lepharamitha (isb, uma amandla e-laser engu-1000W, inani alikho ngaphezu

1000).

④Ibanga lesilinganiso sokulayisha ngu-0~100 (okuzenzakalelayo ngu-100, ngokuvamile asikho isidingo sokushintsha).

Ibanga lokuvama kweshayela elinconyiwe lingu-5-5000Hz (okuzenzakalelayo ngu-2000, ngokuvamile asikho isidingo sokushintsha).

Chofoza inkinobho ethi "Usizo" phezulu kwesokudla ukuze uthole izincazelo ezengeziwe zamapharamitha afanelekile.

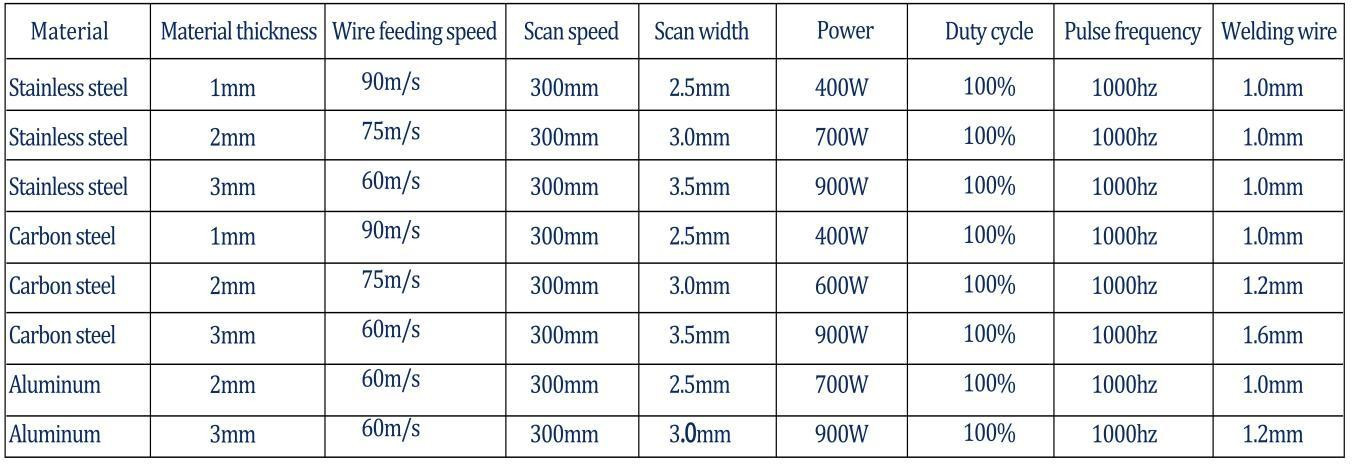

Ireferensi yenqubo (ngokuya ngezimo zangempela, okulandelayo okokubhekisela kuphela)

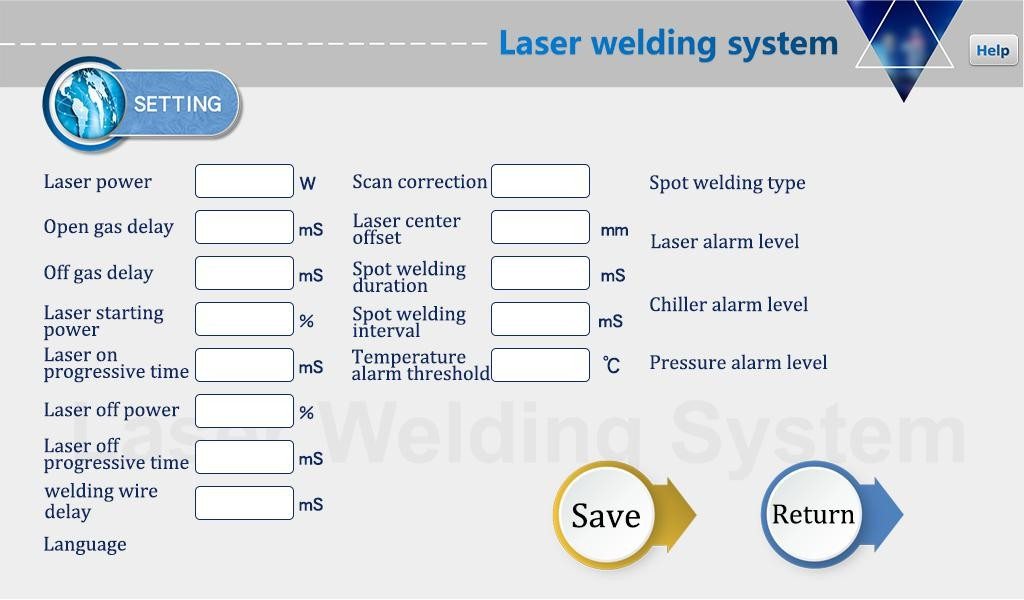

Setha isikrini esikhulu sokusebenza

Inombolo yepholisi: 123456

Amandla e-laser angamandla aphezulu e-laser asetshenzisiwe.

②Ukulibaziseka komoya okushintshayo kungu-200ms ngokuzenzakalelayo, futhi ububanzi bungu-200ms-3000ms.

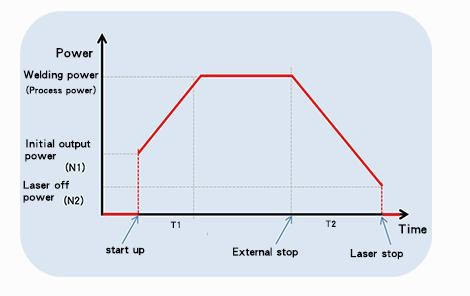

③Ukukhanya kukhanyisa kancane kancane kusuka ku-N1% kuya ku-100% wamandla enqubo;lapho ukukhanya kucishiwe, kancane kancane kukhuphuka kusuka ku-100% wamandla enqubo.

ku-N2;(njengoba kukhonjisiwe emfanekisweni ongezansi).

④Isinxephezelo sokulibaziseka kokuphakelayo komugqa sihlobene nesikhathi sangaphambi kwesikhathi sokuphakelayo komugqa wesignali yokubona futhi singasetshenziswa ngokuhambisana nomsebenzi wokuhlehlisa.

⑤ Umkhawulo we-alamu wezinga lokushisa eliphezulu ngu-70°C.Uma inani lisethelwe ku-0, i-alamu yezinga lokushisa ngeke ibonwe.

⑥Ibanga le-coefficient yokuskena engu-0.01~4, ububanzi bomugqa wethagethi ye-coefficient/ububanzi bomugqa wokulinganisa: ngokuvamile buyi-1.25.

⑦I-laser center offset ingu-3~3mm, yehla iye kwesokunxele bese ikhula iye kwesokudla.

⑧ isignali yezinga le-alamu iyona ezenzakalelayo, i-alamu yesihlangu ingashintshwa ngokuqondile ekutholeni izinga elihambisanayo.

⑨ Ubude besikhathi sokushisela busho isikhathi sokukhipha ukukhanya ngemva kokudonsa i-trigger, okungukuthi, noma inkinobho ikhishiwe, isazokhanya ngokuvumelana nesikhathi esichithiwe (inguqulo ye-V3.3 yomsebenzi ongenhla)

Isikhathi sokuphumula se-spot welding isikhathi sokukhanya kokuma phakathi kokushisela kwamabala amabili ngemva kokudonsa inkinobho yokuqalisa (inguqulo ye-V3.3 yomsebenzi ongenhla)

⑧ Chofoza inkinobho ethi USIZO phezulu kwesokudla ukuze uthole incazelo eyengeziwe yamapharamitha afanelekile.

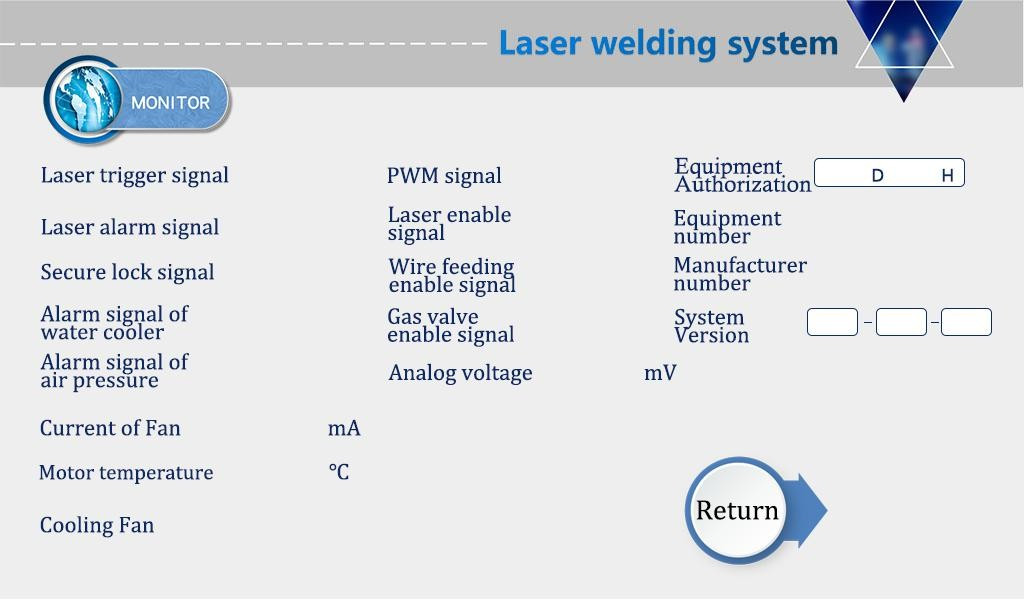

Ukuqapha interface main

Lesi sixhumanisi sibonisa isimo sesignali yokuthola ngayinye nolwazi lwedivayisi

Chofoza ekugunyazweni kwedivayisi ukuze ufake isixhumi esibonakalayo sesikhathi sokusebenzisa esigunyaziwe, ngemva kokufaka iphasiwedi, isistimu ingagunyazwa isikhathi sokusebenzisa Izindlela zokubethela zokugunyazwa nezindlela zokukhipha ukubethela ziyefana:

Indlela yokususa ukubethela kwesistimu

Ukuphepha, Ukugcina Isikhathi, Ukukhanya

Amandla okushisela ikhwalithi, ukuwohloka okuncane, ukujula kokuncibilika okuphezulu, ukuthuthuka okuzinzile.