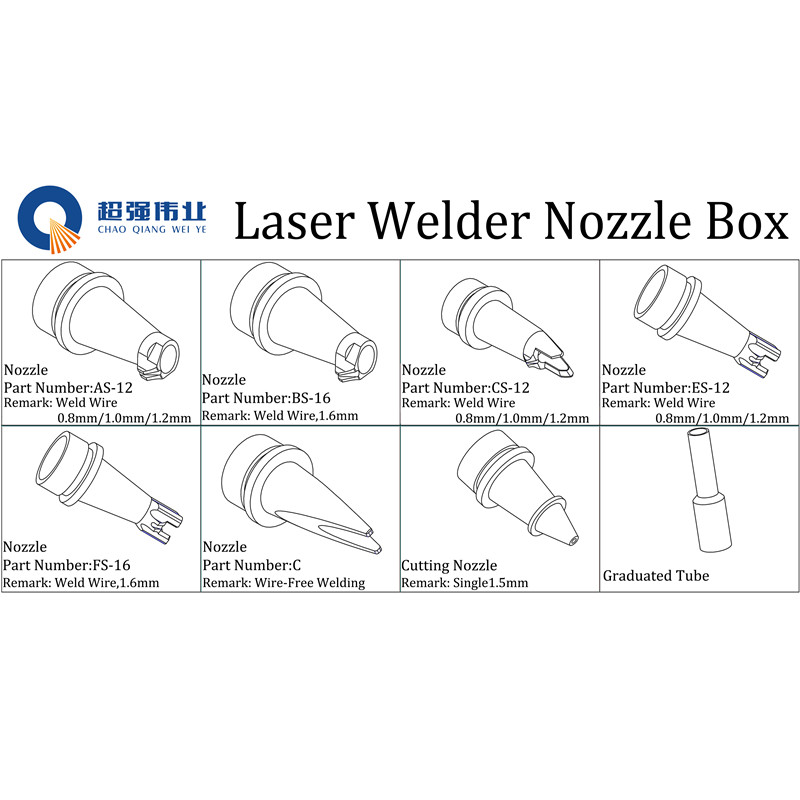

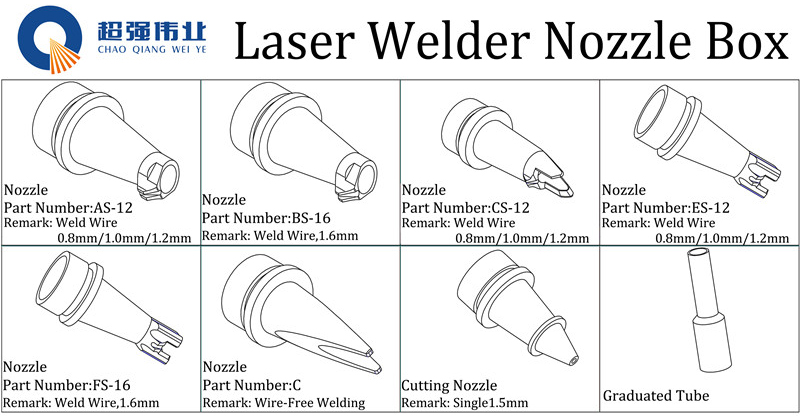

I-Copper Nozzle ye-Welding Head

Inombolo Yengxenye:AS-12

Phawula: Weld Wire 0.8mm/1.0mm/1.2mm

Ingxenye Inombolo:BS-16

Phawula: Weld Wire, 1.6mm

Ingxenye Inombolo:BS-16

Phawula: Weld Wire, 1.6mm

Ingxenye #:ES-12

Phawula i-Weld Wire 0.8mm/1.0mm/1.2 nm

Ingxenye #:FS-16

Phawula: Weld Wire, 1 6mm

Inombolo Yengxenye:C

Phawula: Wire -Free Welding

Inombolo Yengxenye:C

Phawula: Wire -Free Welding

Inombolo Yengxenye:C

Phawula: Wire -Free Welding

Iziqu Tube

Umthelela we-nozzle yomshini wokusika we-laser ekusikeni kwe-laser?

Umshini wokusika i-laser osetshenziswayo uzosebenzisa umlomo wombhobho, imakethe ihlukaniswe ikakhulukazi ngombhobho we-supersonic nozzle we-subsonic, i-supersonic njengoba igama lisho ukuthi izinga lokugeleza kwegesi likhulu kunejubane lomsindo, i-subsonic nozzle izinga lokugeleza kwegesi lincane. kunejubane lomsindo.Ama-nozzles amabili ahlukaniswe abe yizinhlobo ezingavamile kanye nezinhlobo ezimbili.Ake sibheke umthelela we-nozzle yomshini wokusika we-laser lapho usikwa nge-laser.

Umshini wokusika we-laser kabili

Ngaphambi kokusho ukuthi i-nozzle yomshini wokusika i-laser inomthelela ekusikeni kwe-laser, qala usho ukuthi igesi elisizayo lidlala indima ekusikeni.Okokuqala, sheshisa izinga lokupholisa lendawo yokusika, unciphise indawo ethintekile ekushiseni, futhi usize ukwakha indawo yokusika ebushelelezi.Okwesibili, i-oxygen njengegesi elisizayo ingakhuphula ukushisa okusabelayo, okuhambisana kakhulu nokusika kwepuleti eliwugqinsi.Okwesithathu, igesi ye-inert njengegesi elisizayo lingavimbela i-oxidation ye-workpiece, igcine izici zezinto ngokwazo.

1. Ithonya le-oxide viscosity

Phakathi kwayo yonke imingcele yezobuchwepheshe yokusika i-laser, ingcindezi yegesi eyisizayo kanye nezici zokugeleza kwegesi yizici ezibalulekile ezithinta ikhwalithi yokusika.Lapho usika amapuleti ensimbi awugqinsi, njenge-carbon steel, umoya-mpilo usetshenziswa njengegesi elisizayo ngoba ama-iron oxide ane-viscosity ephansi futhi kulula ukuwakhipha ekusikeni.

Ngaphansi kwezimo ezijwayelekile, nakuba uhlangothi lwe-carbon steel laser cutting incision luqukethe ungqimba oluncane lwe-iron oxide, ezimweni eziningi, ikhwalithi ye-laser yokusika i-carbon steel cutting surface iyamukeleka.Kodwa ngenxa yokuthi insimbi engagqwali iqukethe i-chromium, futhi i-chromium oxide encibilikisiwe ine-viscosity ephezulu, kulula ukubopha odongeni oluseceleni lokusikeka, ngakho-ke ukusetshenziswa okufanayo komoyampilo njengegesi elisizayo, ikhwalithi yokucubungula insimbi engagqwali yimbi kune-carbon steel.Uma umfutho wegesi ungekho phezulu, kunzima ukususa la ma-oxide.

Inkinga efanayo izokwenzeka lapho usika i-aluminium ne-titanium alloy, ngoba i-aluminium encibilikisiwe ne-titanium oxide nayo ine-viscosity ephakeme, ukuze uthole ikhwalithi enhle yokusika kufanele idinga ukucindezela okuphezulu kwegesi elisizayo.Eqinisweni, ama-alloys e-Cr, Al, Ti anzima ukusika izinto.

Isibonisi sobuchwepheshe bokusika umshini wokusika i-Laser

2. Ithonya le-slag viscosity esimweni sokuncibilika

Ukusika i-laser ngegesi ye-inert njengegesi eyisiza kunganciphisa umthelela wezinkinga ezingenhla ngezinga elithile, kodwa igesi engasebenzi ngokuvamile idinga ukusebenza endaweni yokucindezela ephezulu kakhulu engu-8 kuya ku-25Bar, futhi insimbi encibilikisiwe ekusikeni ingasuswa. ngaphansi kwesenzo se-airflow shear force.Ngenxa yokuthi awukho umoya-mpilo ekugelezeni, ama-oxide ensimbi ngeke akheke ekusikeni.Ngokuvamile, insimbi ehlanzekile esimweni esincibilikisiwe ine-viscosity ephansi kakhulu kune-oxide yayo futhi ingashaywa kalula, ngakho-ke kulula ukwakha indawo encane ethintekile ukushisa kanye nendawo yokusika ebushelelezi ngaphandle kokungcola kwe-oxide.

Isakhiwo esikhethekile sombhobho we-supersonic cishe singaguqula ingcindezi yegesi eyisiza sibe amandla aguqukayo, sikhiphe i-slag, futhi sifinyelele indawo yokusika ye-laser ephelele kakhulu.